UK farmers hoping that automated systems will fill the gap left by a chronic shortage of seasonal workers for picking crops will have to wait until at least 2030 for the technology to mature, a new report from the Department for Environment Food and Rural Affairs (Defra) says.

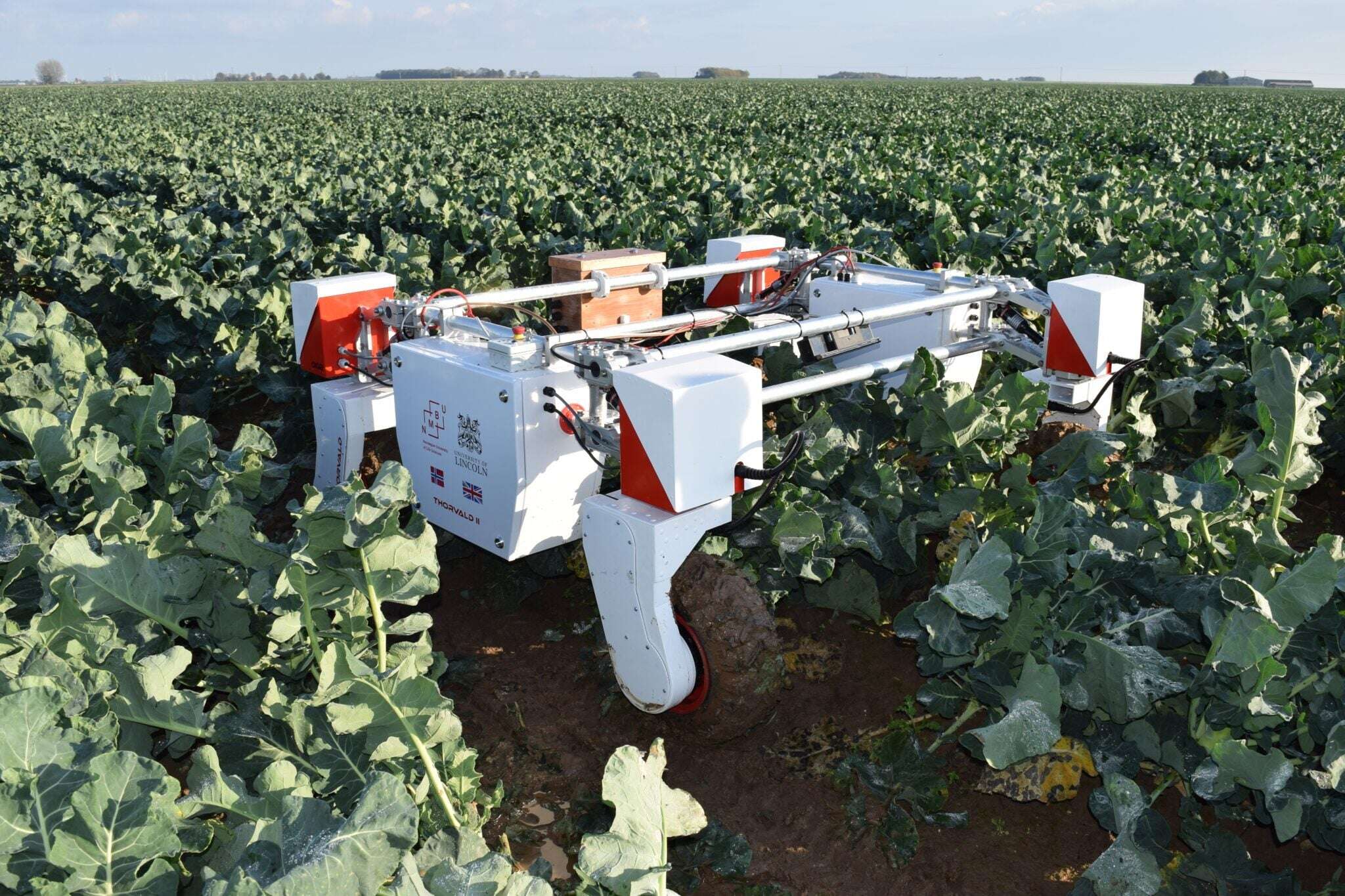

The Defra review shows technologies such as automation, artificial intelligence (AI) and robotics could be deployed to help with harvests and that the horticulture sector was “actively seeking to adopt technologies when proven”. But it also outlines major barriers to innovation such as raising capital for investment and the tech skills shortage which has impacted many sectors.

The Review of Automation in Horticulture describes three waves of technology implementation that can produce labour savings and increase worker productivity. The first wave includes optimised production systems, packing automation and field rigs and mechanical systems – all of which offer minor labour savings and are widely available for mass adoption.

However, the second and third waves are made up of technologies such as autonomous selective crop harvesting, AI and collaborative robotics assisting in harvesting and produce-picking and autonomous crop protection. These are still in development and are not ready for commercialisation due to the significant amounts of capital required. Autonomous selective crop harvesting isn’t expected to be commercialised until after 2030, the review says.

Can agri-tech solve the UK’s seasonal worker problem?

In 2019, there were 63,000 seasonal workers active in horticulture in the UK. However, Brexit and the ending of freedom of movement for EU citizens, together with the effect of the Covid-19 pandemic, means this number has dropped dramatically.

Many growers now do not have enough manpower to harvest fruit, vegetables and herbs, and it creates food wastage. Sky News reported earlier this month that ripe produce was being left unpicked in fields, further contributing to food price inflation. To combat this, the Home Office made 30,000 visas available to seasonal workers, and is looking to increase this to 40,000. But the National Farmer’s Union (NFU) says there is still a 12% shortfall of workers for the sector.

This shortfall is continuing to result in businesses and growers not being able to plan, create a business case and secure investment. Professor Simon Pearson, co-chair of the study and director of Lincoln Institute for Agri-Food Technology, told Tech Monitor that the review found that the industry needs time and resources to be able to plan and secure investment for UK agri-tech projects, but without workers they are struggling to do so because they have to focus on their short-term issues.

Pearson, who is also Professor of Agri-Food Technology at the University of Lincoln, says growers also lack the confidence to invest in automation. The technology has a payback period over many seasons and many producers are only planning one season ahead due to staffing problems, meaning they are unable to commit to long-term investments

Tech systems that are already on the market are of little use without staff to operate them, Pearson says. In this scenario, production would stop, and businesses would be “more likely to fail faster” after making the investment.

Without policy intervention and more investment from private equity investors, it will take at least three to five years for second-wave technologies to start to be implemented by growers, Professor Pearson adds.

SMEs are leading the way in agri-tech innovation

Small and medium enterprises (SMEs) in the technology sector are working hard to develop robotic solutions for the agriculture sector, Pearson told Tech Monitor. Investment in the agri-tech sector has grown consistently with 2021 seeing its biggest increase of 61.4%.

“[SMEs] are starting to get engaged and starting to get robots out in farms,” explains Pearson. “That’s a key milestone.”

He adds that two years ago, only two companies were working on robots in agriculture, whereas now there are seven or eight. But there are cost, as well as technological, challenges to solve, with robotic picking systems currently significantly more expensive than hiring human staff. “There are a lot of people working hard to try and get these things economically sustainable,” Professor Pearson says.

This article originally appeared on Tech Monitor.